Tuesday, December 12, 2017

Looking Back-First Run

Here's a photo of the layout after track laying and wiring. The "official" first run of the Wetterau Food Services Micro Layout in December of 2014!

Wednesday, September 27, 2017

Building the WFS Part 9

(Originally published on the Micro Model Railroad Cartel Blog)

The completed layout!

The layout reached this point on February 20, 2016.

If you have any questions regarding this layout, feel free to contact me at this email address: otmodelrr[at]gmail[dot]com

Tom

The completed layout!

The layout reached this point on February 20, 2016.

If you have any questions regarding this layout, feel free to contact me at this email address: otmodelrr[at]gmail[dot]com

Tom

Tuesday, August 29, 2017

Building the WFS Part 8

The Final Stage

(Originally published on the Micro Model Railroad Cartel Blog)

Track ballast is in place and final scenery work begins.

A few more finishing touches are needed on the warehouse structure. I did not copy the prototype structure exactly and used plastic detail parts to hide seams and flaws in the cardstock/foam core building flat.

Disaster...

I didn't realize I had placed the building flat directly under a seam on my folding table. Isopropyl alcohol and scenic cement leaked through the seam and dropped down on the building flat. My carelessness ended up damaging the photo front on the building flat. I also discovered my ink jet printer was low on ink and the replacement brick front didn't match the undamaged portion of the brick on the building flat. Ugh!

Disaster fixed...

I went ahead and pulled off all of the brick facing on the building flat and replaced the whole front. This ended up being an easy fix, and I was even able to adjust the seams and get rid of the vent pipe that was used on the previous version of the building flat. I like this version better than the previous one, so it turned out to be a blessing in disguise!

The connecting track section pieces were ballasted using a piece of .010 styrene glued to the bottom of the ties/sleepers and ballast applied to the topside of the track section. This technique worked well and I am happy with the results.

IMPORTANT OBSERVATION:

Despite all of the isopropyl alcohol and scenery cement poured onto the foam core baseboard, warping has been slight. This warping has not created any issues with connections or any vertical deflections to the track. Overall it has been a pleasant experience. Proper bracing of the baseboard is key to minimize warping of the baseboard.

Tom

Sunday, August 13, 2017

Building the WFS Part 7

(Originally published on the Micro Model Railroad Cartel Blog.)

Basic Backdrop Painting and Static Grass

I painted the backdrop sections a basic sky color. The plan was to add a photo backdrop to the scene as well as painting a few background trees and clouds...nothing fancy. I ended up painting a few buildings and scenery elements instead of using a photo backdrop. The painted backdrop will eventually be replaced with a photo backdrop.

The next step was to begin adding another layer of texture to the scenery base. I used a homemade static grass applicator and a static grass blend from Noch for this step of the scenery process. More textures will be added before calling this scene complete.

That's all for now!!

Tom

Basic Backdrop Painting and Static Grass

I painted the backdrop sections a basic sky color. The plan was to add a photo backdrop to the scene as well as painting a few background trees and clouds...nothing fancy. I ended up painting a few buildings and scenery elements instead of using a photo backdrop. The painted backdrop will eventually be replaced with a photo backdrop.

|

| background details painted with acrylic paints |

The next step was to begin adding another layer of texture to the scenery base. I used a homemade static grass applicator and a static grass blend from Noch for this step of the scenery process. More textures will be added before calling this scene complete.

That's all for now!!

Tom

Sunday, August 6, 2017

Building the WFS Part 6

(Originally published on the Micro Model Railroad Cartel Blog)

Painting and Ballasting Track

I like to paint and weather the rails and the individual ties/sleepers before applying ballast. I use acrylic paints (Raw Sienna, Raw Umber, Payne's Gray, and Unbleached Titanium) and paint the individual ties/sleepers in a random fashion. The rails are painted with a Floquil Paint Pen (Rail Brown).

I like to use a blend of Monster Modelworks Diorama Dirt (sifted) and Woodland Scenics Fine Gray Ballast to ballast the track. I carefully apply the ballast material being sure to keep ballast grains clear of frogs, guardrails, and turnout throwbars. I like to use 70% Isopropyl Alcohol as a wetting agent, and Woodland Scenics Scenic Cement to fasten the ballast into place. The alcohol and scenic cement are applied with a pipette. The photos below show the various stages of painting ties/sleepers and ballasting track.

Painting and Ballasting Track

I like to paint and weather the rails and the individual ties/sleepers before applying ballast. I use acrylic paints (Raw Sienna, Raw Umber, Payne's Gray, and Unbleached Titanium) and paint the individual ties/sleepers in a random fashion. The rails are painted with a Floquil Paint Pen (Rail Brown).

I like to use a blend of Monster Modelworks Diorama Dirt (sifted) and Woodland Scenics Fine Gray Ballast to ballast the track. I carefully apply the ballast material being sure to keep ballast grains clear of frogs, guardrails, and turnout throwbars. I like to use 70% Isopropyl Alcohol as a wetting agent, and Woodland Scenics Scenic Cement to fasten the ballast into place. The alcohol and scenic cement are applied with a pipette. The photos below show the various stages of painting ties/sleepers and ballasting track.

Sunday, July 23, 2017

Building the WFS Part 5

(Originally published on the Micro Model Railroad Cartel Blog)

Scenery Work

I have applied a base coat of paint to the ground and track. I also filled in the foam core roadbed sides with Sculptamold. I like to add some earth-colored latex paint to the water before I add the dry Sculptamold. Adding this color tones down the stark white of the Sculptamold. I used a palette knife to mix, apply, and smooth the Sculptamold.

The road through the scene was made with a foam core base and Woodland Scenics' Smooth-It applied over it. I applied the Smooth-It with a palette knife. I used an old freight truck, screwdriver, and Bright Boy track cleaner to keep the flangeways and rail tops clear of the plaster.

Tom

Scenery Work

I have applied a base coat of paint to the ground and track. I also filled in the foam core roadbed sides with Sculptamold. I like to add some earth-colored latex paint to the water before I add the dry Sculptamold. Adding this color tones down the stark white of the Sculptamold. I used a palette knife to mix, apply, and smooth the Sculptamold.

The road through the scene was made with a foam core base and Woodland Scenics' Smooth-It applied over it. I applied the Smooth-It with a palette knife. I used an old freight truck, screwdriver, and Bright Boy track cleaner to keep the flangeways and rail tops clear of the plaster.

Tom

Tuesday, April 11, 2017

Building the WFS Part 4

(Originally published on the Micro Model Railroad Cartel Blog)

This is a video showing how I wired the layout and connected the baseboard sections together.

This is a video showing how I wired the layout and connected the baseboard sections together.

Saturday, March 11, 2017

Building The WFS Part 3

(Originally published on the Micro Model Railroad Cartel Blog)

Laying Track

The photos below show how the track was laid. I am using Atlas code 100 track on this micro. I used wood glue since it is resistant to water/alcohol after it has dried. It has a fairly strong bond but is not too hard to pry up if you accidently glue a piece of track that is not supposed to be glued down. A nice feature of foam core board is you can use push pins to hold everything down while the glue dries. I was careful not to get any glue under the removable track sections. After the glue had dried, I glued individual plastic railroad ties under the rail sections where gaps were present. Everything is staying put, even with extreme humidity changes.

Up next: video on how I wired the layout

Laying Track

The photos below show how the track was laid. I am using Atlas code 100 track on this micro. I used wood glue since it is resistant to water/alcohol after it has dried. It has a fairly strong bond but is not too hard to pry up if you accidently glue a piece of track that is not supposed to be glued down. A nice feature of foam core board is you can use push pins to hold everything down while the glue dries. I was careful not to get any glue under the removable track sections. After the glue had dried, I glued individual plastic railroad ties under the rail sections where gaps were present. Everything is staying put, even with extreme humidity changes.

Up next: video on how I wired the layout

Friday, February 17, 2017

Building the WFS Part 2

(Originally published on the Micro Model Railroad Cartel Blog.)

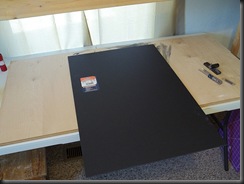

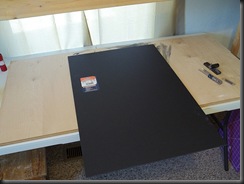

Using Foam Core Board For The Layout Sections

I constructed this micro layout from foam core sheets. The sheet size is 20 inches x 30 inches and I chose black foam core sheets (About 3 sheets total used for all sections). I used a construction method I received from a PowerPoint presentation by Prof. Klyzlr* on a past episode of Model Rail Radio. One slide illustrates Chris Ellis’ method of using flat modules connected with foam core clips (Clipboard Modules). Some really nice illustrations by Jack Trollope, which were included in Prof. Klyzlr’s presentation*, aided me in putting this all together. I modified the dimensions to fit my needs and used Pacer Industries Formula 560 Canopy Glue to fasten the parts together. The left section’s dimensions are 7.5 inches wide by 30 inches long with a box depth of 40mm. The right section is 7.5 inches wide by 24 inches long with a box depth of 40mm as well. The left staging section (not pictured) is 2 inches wide by 13.5 inches long with a box depth of 40mm. The right staging section (not pictured) is 3.5 inches wide by 28 inches long with a box depth of 40mm.

Below are photos of the main modules under construction.

The clip is really good at holding the two sections together. So far, I am not experiencing any warping. That may change with the addition of scenery.

Up Next: Laying Track

*Due to copyright, I am not able to post Prof. Klyzlr’s PowerPoint presentation, “Foamcore Modules: A Different Approach to Layout Construction.”

Using Foam Core Board For The Layout Sections

I constructed this micro layout from foam core sheets. The sheet size is 20 inches x 30 inches and I chose black foam core sheets (About 3 sheets total used for all sections). I used a construction method I received from a PowerPoint presentation by Prof. Klyzlr* on a past episode of Model Rail Radio. One slide illustrates Chris Ellis’ method of using flat modules connected with foam core clips (Clipboard Modules). Some really nice illustrations by Jack Trollope, which were included in Prof. Klyzlr’s presentation*, aided me in putting this all together. I modified the dimensions to fit my needs and used Pacer Industries Formula 560 Canopy Glue to fasten the parts together. The left section’s dimensions are 7.5 inches wide by 30 inches long with a box depth of 40mm. The right section is 7.5 inches wide by 24 inches long with a box depth of 40mm as well. The left staging section (not pictured) is 2 inches wide by 13.5 inches long with a box depth of 40mm. The right staging section (not pictured) is 3.5 inches wide by 28 inches long with a box depth of 40mm.

Below are photos of the main modules under construction.

The clip is really good at holding the two sections together. So far, I am not experiencing any warping. That may change with the addition of scenery.

Up Next: Laying Track

*Due to copyright, I am not able to post Prof. Klyzlr’s PowerPoint presentation, “Foamcore Modules: A Different Approach to Layout Construction.”

Sunday, February 12, 2017

The Warrior Express Train Show

The Wetterau Food Services Micro Layout made its first trip to a local train show yesterday. It was a lot of fun, and I really enjoyed the experience.

The Warrior Express Train Show (February 11, 2017)

Tom

The Warrior Express Train Show (February 11, 2017)

Tom

Building the WFS Part 1

(Originally published on the Micro Model Railroad Cartel Blog)

The Inspiration and Track Plan

The Wetterau Food Services layout is based on a grocery distributor that once existed in the town of Desloge, Missouri. The structure and tracks still exist, but it is no longer a grocery distributor or receives rail service. This location is the inspiration for a micro layout I am currently building. Although the track arrangement is very close to the actual prototype, this layout will not be a faithful model of that prototype. This location was once served by the Mississippi River & Bonne Terre, Missouri & Illinois, and the Missouri Pacific Railroad. Today, the line is owned and operated by Union Pacific.

Reference Photos of the Prototype:

HO Track Plan:

Up Next in Part 2: Using Foam Core Board For The Layout Sections

The Inspiration and Track Plan

The Wetterau Food Services layout is based on a grocery distributor that once existed in the town of Desloge, Missouri. The structure and tracks still exist, but it is no longer a grocery distributor or receives rail service. This location is the inspiration for a micro layout I am currently building. Although the track arrangement is very close to the actual prototype, this layout will not be a faithful model of that prototype. This location was once served by the Mississippi River & Bonne Terre, Missouri & Illinois, and the Missouri Pacific Railroad. Today, the line is owned and operated by Union Pacific.

Reference Photos of the Prototype:

HO Track Plan:

Up Next in Part 2: Using Foam Core Board For The Layout Sections

Subscribe to:

Comments (Atom)